Understanding a 6 Pin DC CDI wiring diagram is crucial for anyone working with small engines, especially motorcycles, scooters, and ATVs. This diagram provides the roadmap for how the Capacitor Discharge Ignition (CDI) unit, a vital component for spark generation, connects to the rest of the engine's electrical system. Navigating a 6 Pin DC CDI wiring diagram ensures proper installation, troubleshooting, and repair of your ignition system.

What is a 6 Pin DC CDI Wiring Diagram and How It Works

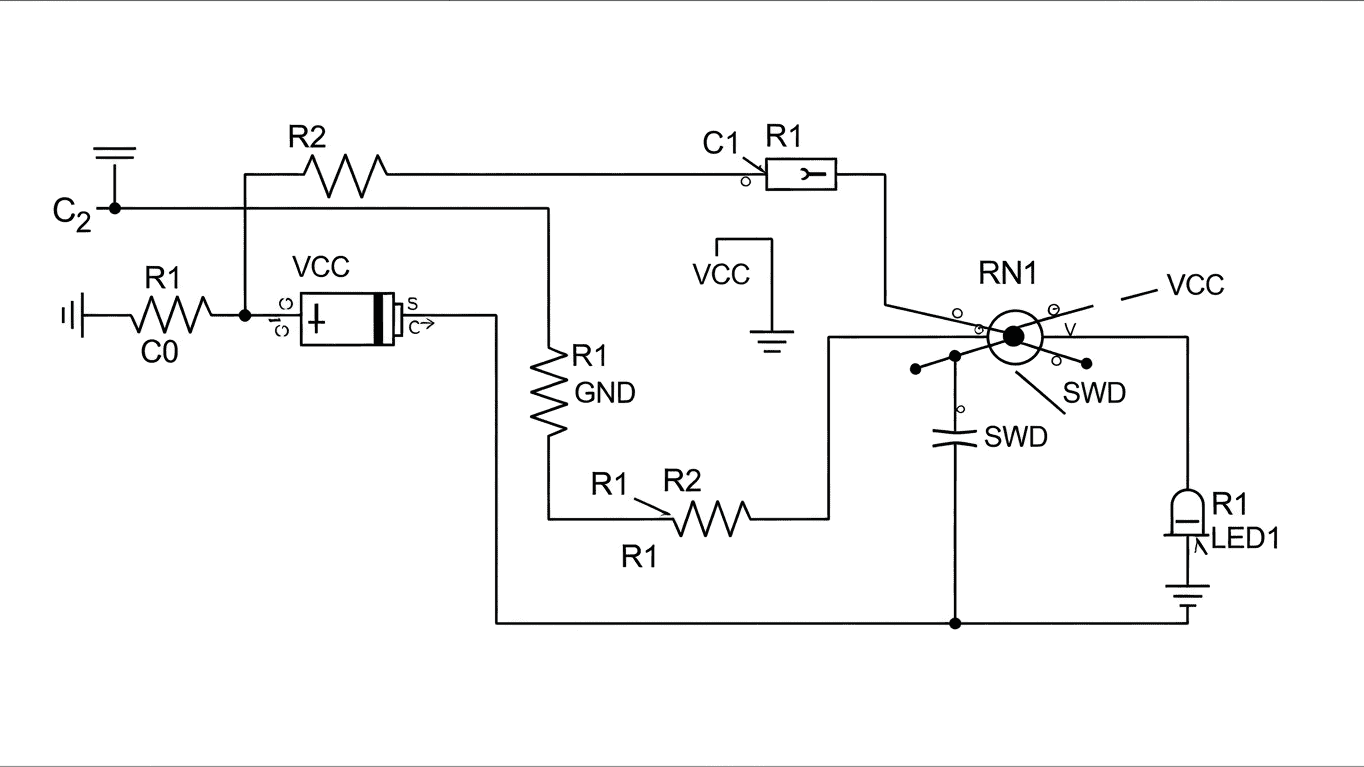

A 6 Pin DC CDI wiring diagram illustrates the connections between the CDI module, the power source, ignition coil, and various sensors. Unlike AC CDI systems, DC systems draw their primary power from the vehicle's battery, offering more consistent performance and easier starting. The CDI unit itself stores electrical energy in a capacitor and then rapidly discharges it through the ignition coil to create a high-voltage spark at the spark plug, igniting the fuel-air mixture. The correct wiring is essential for the CDI to function properly and deliver a reliable spark.

Here's a general breakdown of common pins and their functions found in a typical 6 Pin DC CDI wiring diagram:

- Power Input (+12V DC): This is where the CDI receives its operating voltage, usually from the battery or a regulated DC output.

- Ground: The chassis or negative terminal of the battery provides a reference point for the electrical circuit.

- Engine Kill Switch: This pin connects to the engine's kill switch, which grounds the CDI circuit to stop the engine.

- Pick-up Coil Signal: This wire receives a signal from the pick-up coil (also known as a pulse generator) on the engine's flywheel. This signal tells the CDI when to fire the spark plug, synchronized with the engine's rotation.

- Ignition Coil Trigger: This is the output that sends the high-voltage pulse to the ignition coil.

- Sometimes a Tachometer Output or other sensor connection (this pin's function can vary depending on the specific CDI model).

When the engine rotates, the pick-up coil generates a pulse. This pulse signals the CDI to charge its capacitor from the DC power source. Once the capacitor is charged and the engine's piston is in the correct position (detected by the pick-up coil signal), the CDI rapidly discharges the capacitor's energy into the ignition coil. This creates a powerful spark that jumps across the spark plug gap, initiating combustion. Without a correct 6 Pin DC CDI wiring diagram, connecting these components could lead to the CDI failing, the engine not starting, or even damage to other electrical parts.

To ensure you have the most accurate information for your specific application, please refer to the detailed 6 Pin DC CDI wiring diagram provided in the technical documentation for your vehicle or the CDI unit manufacturer's guide.