Navigating the electrical connections of a motor can sometimes feel complex. For those working with motors that have six wires, understanding the specifics of a 6 Wire Motor Wiring Diagram is crucial for proper installation, troubleshooting, and safe operation. This guide will break down what these diagrams represent and how they serve as an essential tool for anyone interacting with these types of motors.

The Essentials of a 6 Wire Motor Wiring Diagram

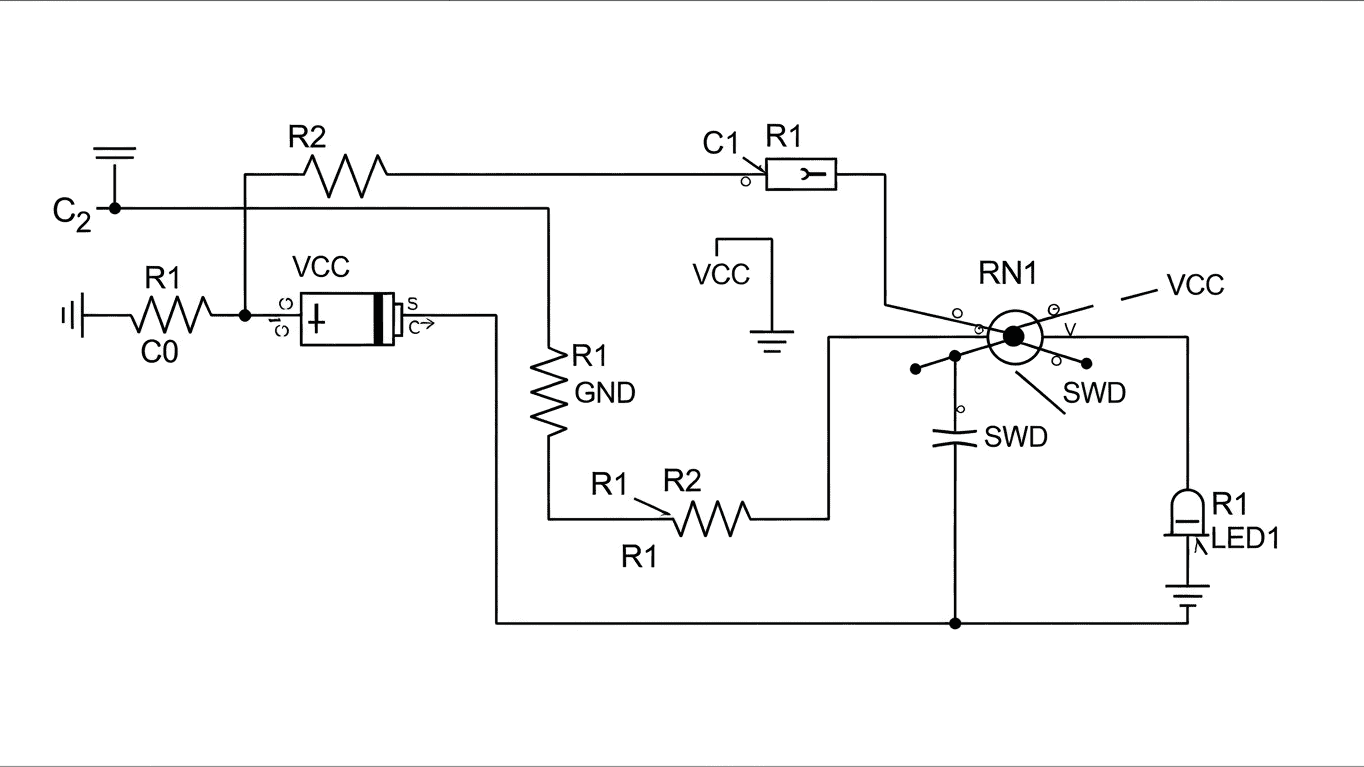

A 6 Wire Motor Wiring Diagram is a visual blueprint that illustrates the internal winding configuration and connection points of a specific type of electric motor. These motors typically employ a dual winding design, often found in dual-speed or dual-voltage applications. The six wires emerging from the motor housing represent the different ends of these windings, and the diagram shows how these wires are intended to be connected to a power source to achieve desired operating parameters, such as speed or direction. The accurate interpretation of a 6 Wire Motor Wiring Diagram is vital for preventing motor damage, electrical hazards, and ensuring optimal performance.

These diagrams are indispensable for various scenarios. For instance, when setting up a new motor, the diagram guides electricians and technicians through the correct connections to achieve the desired voltage or speed. When troubleshooting a malfunctioning motor, the diagram acts as a reference to identify potential issues within the winding connections. Common applications for motors requiring a 6 Wire Motor Wiring Diagram include:

- Dual-speed fans

- Pumps with variable speed requirements

- Some types of compressors

- Machinery requiring different operational speeds

The specific arrangement of the six wires depends on the motor's design. Generally, they represent the start and end of two distinct windings. A common configuration involves:

- Wire 1: Start of Winding A

- Wire 2: End of Winding A

- Wire 3: Start of Winding B

- Wire 4: End of Winding B

- Wire 5: Common wire (often shared between windings)

- Wire 6: Another common wire or a specific tap

The diagram will then clearly depict how to connect these wires in series or parallel, or to a capacitor, to achieve different voltages (e.g., 120V vs. 240V) or speeds (e.g., high speed vs. low speed). A simplified table illustrating a common dual-voltage setup might look like this:

| Voltage | Connection Example |

|---|---|

| Low Voltage (e.g., 120V) | Connect wires 1, 3, and 5 together; connect wires 2 and 4 to Line 1; connect wire 6 to Line 2. |

| High Voltage (e.g., 240V) | Connect wires 1 and 2 together; connect wires 3 and 4 together; connect wires 5 and 6 to Line 1 and Line 2 respectively (or vice versa). |

To ensure you have the correct wiring for your specific motor and application, always refer to the manufacturer-provided 6 Wire Motor Wiring Diagram that came with your unit. This detailed document will offer precise instructions tailored to your particular motor model.