Navigating the world of stepper motors can sometimes feel like deciphering a secret code, especially when you encounter the various wiring configurations. A 6 Wire Stepper Motor Wiring Diagram is crucial for anyone looking to connect and control these versatile motors. Whether you're a hobbyist building a 3D printer or an engineer designing a robotic arm, understanding this diagram ensures your motor performs as intended.

What is a 6 Wire Stepper Motor Wiring Diagram and How is it Used?

A 6 wire stepper motor is a type of electric motor that divides a full rotation into a number of equal steps. The "6 wire" designation refers to the number of electrical leads emanating from the motor. These wires connect to two independent sets of windings, also known as coils, within the motor. Each set of windings typically consists of two wires. The remaining two wires are usually common leads for these winding sets. Properly understanding and applying the 6 Wire Stepper Motor Wiring Diagram is essential for preventing motor damage, ensuring optimal performance, and achieving precise motion control.

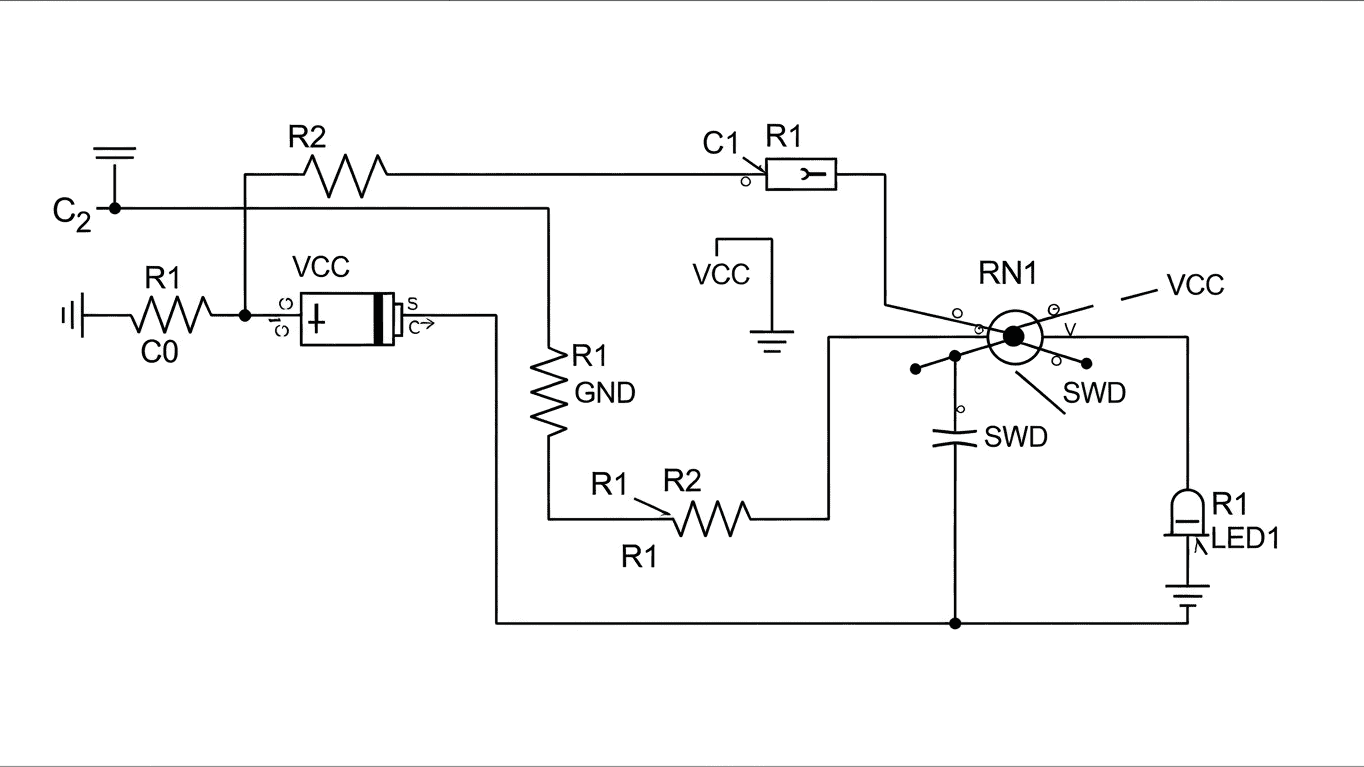

The primary use of a 6 Wire Stepper Motor Wiring Diagram is to guide the connection between the motor and its driver circuit. Stepper motors require a driver to energize their windings in a specific sequence, causing the rotor to rotate step by step. There are several ways to wire a 6-wire stepper motor, each affecting its performance characteristics:

- Series connection: This configuration connects the two halves of each winding in series, increasing the motor's inductance and torque at lower speeds but reducing its maximum speed.

- Parallel connection: In this setup, the two halves of each winding are wired in parallel. This reduces inductance, allowing for higher speeds and potentially more torque at those higher speeds, but it draws more current.

- Unipolar drive: While less common for 6-wire motors (more typical for 5 or 8 wire), it's conceptually possible to treat the center taps if they were present or to reconfigure for unipolar operation with an appropriate driver.

The table below summarizes the typical winding structure:

| Coil Set | Wires |

|---|---|

| Coil A | A1, A2 (or A+, A-) |

| Coil B | B1, B2 (or B+, B-) |

| Common Leads | C1, C2 (often connected to A+ and B+ or ground depending on driver) |

The choice between series and parallel wiring depends heavily on the desired application and the capabilities of the stepper motor driver being used. A detailed 6 Wire Stepper Motor Wiring Diagram will clearly illustrate these connection points and guide you through the process of selecting the correct configuration.

For a comprehensive guide and to ensure you have the most accurate information for your specific motor, please refer to the detailed diagrams and explanations available in the section below.