Understanding the 6.0 Powerstroke Crank Sensor Wiring Diagram is essential for any owner or mechanic working on these robust diesel engines. This diagram provides a crucial roadmap for how the crankshaft position sensor communicates with the engine control module (ECM). Without a proper understanding of this wiring, diagnosing starting issues or engine performance problems can be incredibly frustrating.

The Heart of the Ignition System: What the Crank Sensor Wiring Does

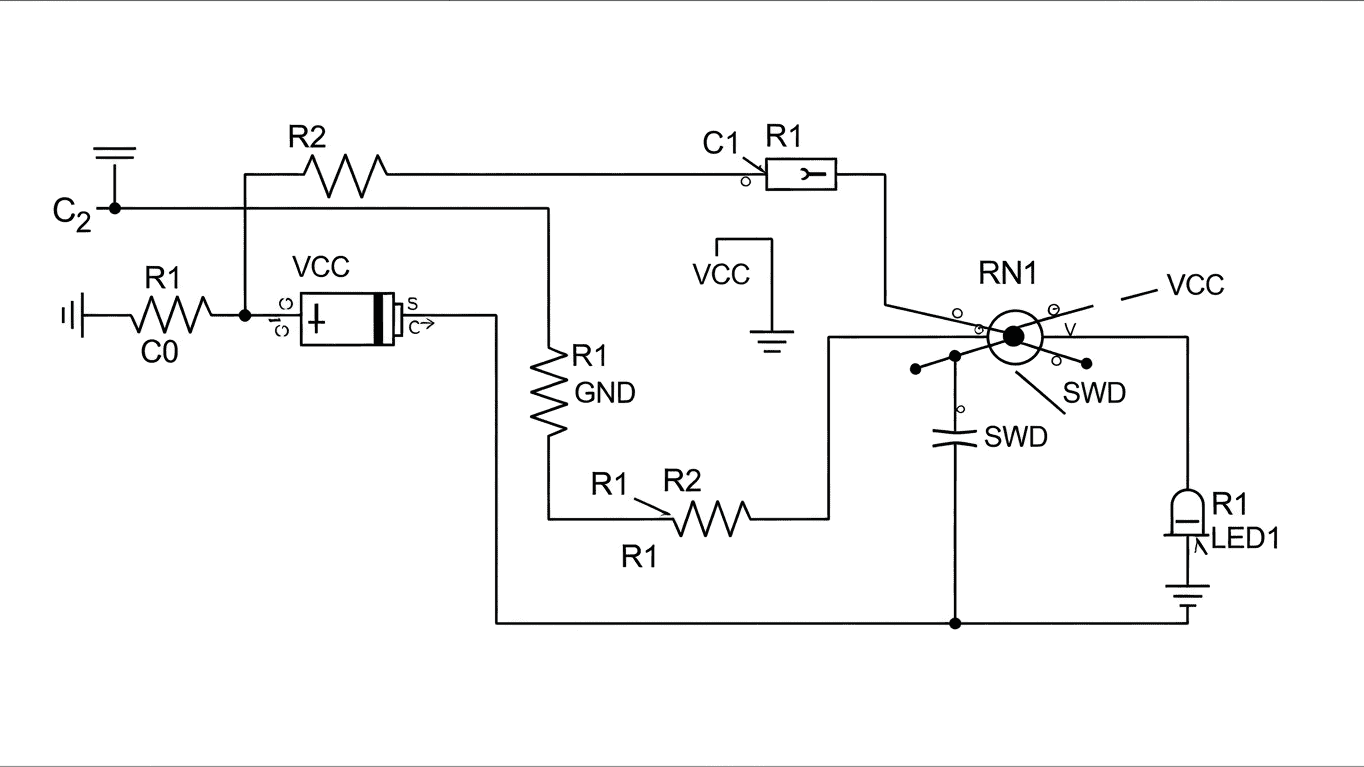

The crankshaft position sensor, or CKP, is a vital component in the 6.0 Powerstroke's ignition and fuel injection system. Its primary job is to tell the ECM the exact rotational speed and position of the crankshaft. This information is fundamental for the ECM to precisely time fuel injector pulses and spark events. The 6.0 Powerstroke Crank Sensor Wiring Diagram illustrates the connections between this sensor and the ECM, including the specific wires for power, ground, and the signal itself. Without accurate data from the crank sensor, the engine simply won't run.

The wiring itself is relatively straightforward, but its integrity is paramount. Typically, the crank sensor circuit involves three wires:

- A power supply wire, usually from the ECM.

- A ground wire, also connected to the ECM or chassis ground.

- A signal wire that transmits the sensor's output back to the ECM.

Diagnosing issues related to the crank sensor often involves consulting the 6.0 Powerstroke Crank Sensor Wiring Diagram to trace the circuit. Common troubleshooting steps include:

- Checking for voltage at the sensor connector.

- Testing for continuity to ground from the ground wire.

- Monitoring the signal wire with an oscilloscope or diagnostic scanner while the engine is cranking.

A table like this might appear in detailed manuals:

| Wire Color | Function | ECM Pin |

|---|---|---|

| Gray | Signal | ECM Connector (Specific Pin) |

| Black/Orange | Power | ECM Connector (Specific Pin) |

| Black | Ground | Chassis Ground or ECM Connector (Specific Pin) |

For accurate and in-depth information, consult the specific 6.0 Powerstroke Crank Sensor Wiring Diagram provided in your vehicle's service manual or a reputable online diagnostic resource dedicated to Ford Powerstroke engines.