Understanding the 6.0 Powerstroke Wiring Diagram is crucial for anyone working on these robust diesel engines. Whether you're a seasoned mechanic or a DIY enthusiast, having a clear grasp of this complex system can save you time, frustration, and potentially costly repairs. The 6.0 Powerstroke Wiring Diagram serves as the electrical roadmap for your engine, detailing every connection and circuit.

What is a 6.0 Powerstroke Wiring Diagram?

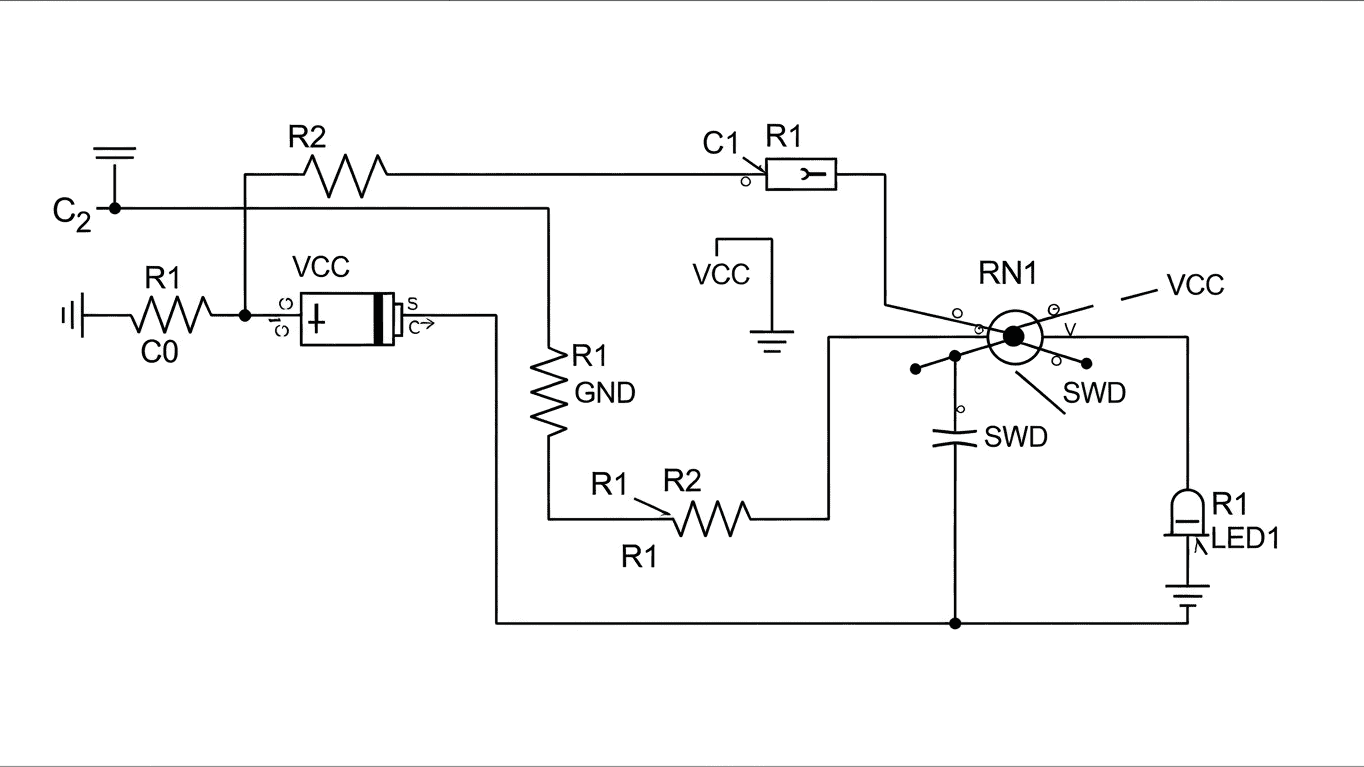

A 6.0 Powerstroke Wiring Diagram is essentially a schematic that illustrates the intricate network of wires, connectors, sensors, and electronic control modules (ECMs) within your Ford truck's engine. It breaks down the complex electrical pathways into a digestible format, making it easier to identify components and understand how they communicate with each other. These diagrams are indispensable for troubleshooting electrical issues, performing modifications, or simply gaining a deeper understanding of your engine's operation. The importance of a correct and detailed 6.0 Powerstroke Wiring Diagram cannot be overstated; it is the key to accurate diagnostics and effective repairs.

These diagrams are not static; they can vary slightly depending on the specific year and options of the 6.0 Powerstroke. Key components typically represented on a 6.0 Powerstroke Wiring Diagram include:

- Engine Control Module (ECM) and its pinouts

- Fuel injectors and their associated wiring

- Sensors such as the Crankshaft Position Sensor, Camshaft Position Sensor, Mass Airflow Sensor, and Exhaust Gas Temperature (EGT) sensors

- Glow plug system

- Ignition system components

- Various relays and fuses

- Wiring harnesses for different engine functions

When diagnosing a problem, a mechanic will often refer to the 6.0 Powerstroke Wiring Diagram to:

- Locate specific wires and their corresponding terminals.

- Trace the path of electrical signals from sensors to the ECM.

- Identify the function of different circuits and components.

- Perform continuity and voltage tests at specific points.

Below is a simplified representation of common sensor connections you might find on a 6.0 Powerstroke:

| Sensor | Typical ECM Pin (Example) | Function |

|---|---|---|

| Crankshaft Position Sensor | A12 | Engine speed and timing |

| Mass Airflow Sensor | B25 | Air intake volume |

| EGR Position Sensor | C18 | Exhaust Gas Recirculation valve position |

Having access to a reliable 6.0 Powerstroke Wiring Diagram is essential for any maintenance or repair work. If you're looking for the most accurate and comprehensive resource, refer to the detailed diagrams available in the following section.