Navigating the intricate electrical systems of modern diesel engines can feel like deciphering a secret code. For owners and mechanics alike, understanding the 6.7 Cummins ECM wiring diagram is a crucial step in diagnosing issues, performing upgrades, or simply gaining a deeper appreciation for the technology under the hood. This guide will shed light on what this vital component represents and why it's so important.

Understanding the 6.7 Cummins ECM Wiring Diagram

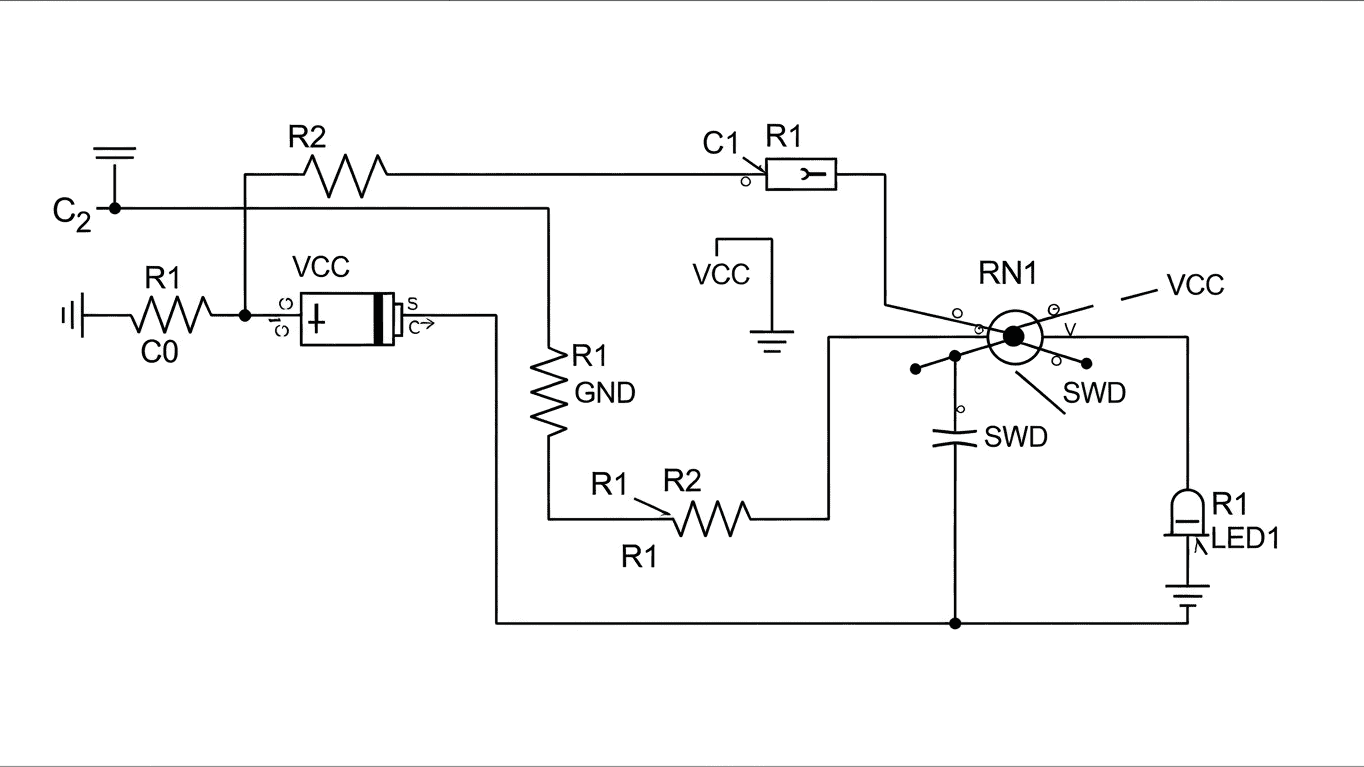

The 6.7 Cummins ECM wiring diagram is essentially a roadmap for the engine's brain, the Electronic Control Module (ECM). It illustrates all the connections between the ECM and the various sensors, actuators, and other electronic components that make the engine run. Think of it as the blueprint that shows where every wire goes, what its purpose is, and how it communicates with the ECM. Without this diagram, troubleshooting electrical problems would be an almost impossible task. The importance of having an accurate 6.7 Cummins ECM wiring diagram cannot be overstated when it comes to maintaining the health and performance of your truck.

These diagrams are indispensable tools for several reasons. Mechanics rely on them to quickly identify faulty sensors, pinpoint open circuits, or trace short circuits that could be causing drivability issues. Technicians can use the diagram to understand the signal pathways for fuel injectors, turbocharger wastegates, EGR valves, and numerous other systems. For those looking to install aftermarket performance modules or make custom modifications, the wiring diagram is the first place to turn to ensure proper integration without damaging the existing electronics. Some of the key components typically depicted include:

- Power and Ground connections

- Sensor inputs (e.g., Crankshaft Position, Camshaft Position, MAP, EOT, EGT)

- Actuator outputs (e.g., Injector drivers, Turbocharger control)

- Communication lines (e.g., CAN bus)

- Diagnostic ports

The information presented in a 6.7 Cummins ECM wiring diagram is typically organized in a logical manner, often with color-coded wires and clear labeling for each connection point. Many diagrams also include tables that provide additional details about specific pins, such as voltage readings, signal types, and expected resistance values. For example, a typical section might look like this:

| ECM Pin | Wire Color | Component Connected | Function |

|---|---|---|---|

| C1-12 | Orange | Manifold Absolute Pressure (MAP) Sensor | Measures intake manifold air pressure |

| C2-05 | Blue/White | Fuel Rail Pressure (FRP) Sensor | Monitors fuel pressure in the common rail |

Whether you're a seasoned diesel mechanic or a hands-on owner, having a reliable 6.7 Cummins ECM wiring diagram will significantly streamline any work you need to do on your vehicle.

For detailed and accurate schematics, refer to the comprehensive resources available in the section that follows.