The 6.7 Powerstroke engine is a marvel of modern engineering, and at its heart lies a complex network of electrical signals. Understanding the 6.7 Powerstroke Engine Wiring Diagram is crucial for anyone who owns, maintains, or repairs these powerful diesel trucks. This diagram serves as the blueprint for how all the electrical components communicate, ensuring optimal performance and reliability.

The Essential Blueprint: What is a 6.7 Powerstroke Engine Wiring Diagram?

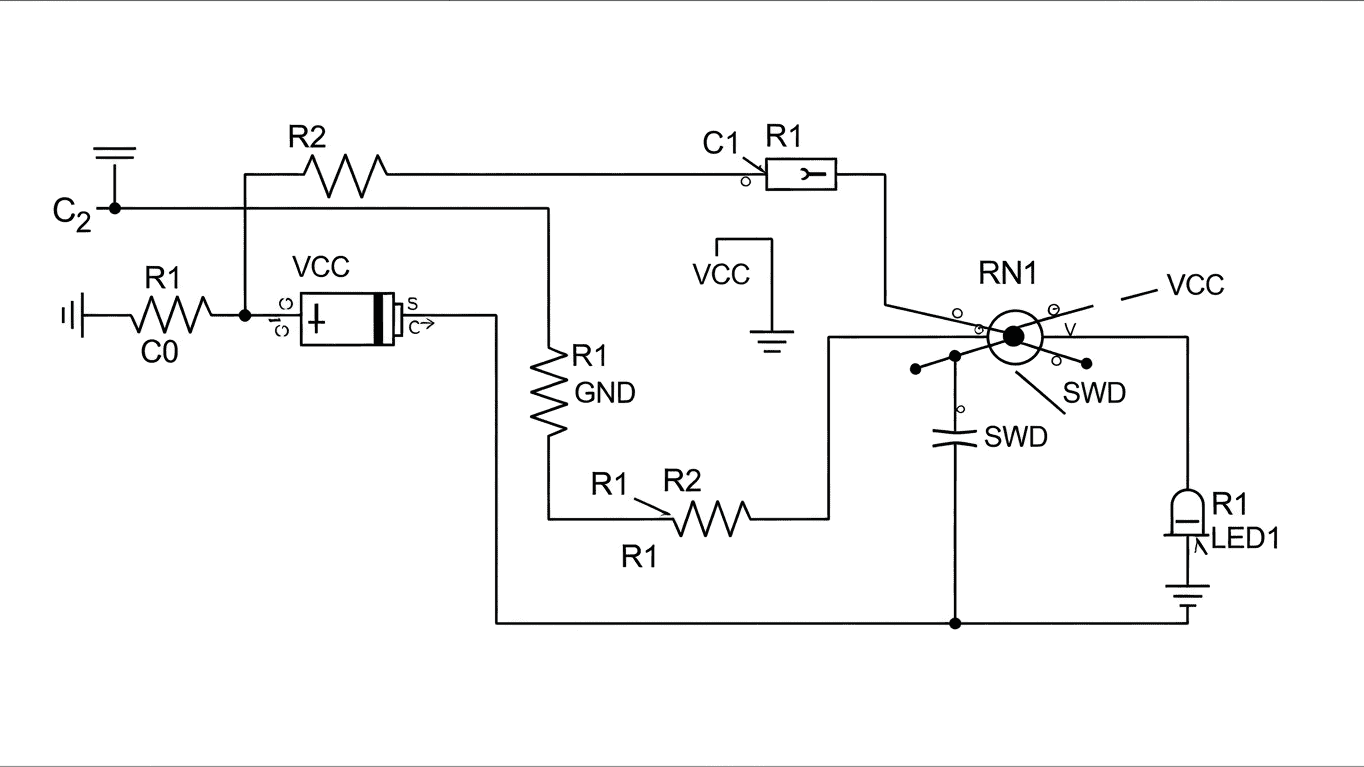

At its core, a 6.7 Powerstroke Engine Wiring Diagram is a visual representation of all the electrical circuits within the engine. It details every wire, connector, sensor, actuator, and control module, showing how they are interconnected. Think of it as a road map for electricity. Without this map, tracing a fault or understanding how a specific system functions would be nearly impossible. Mechanics and technicians rely heavily on these diagrams to diagnose issues, perform repairs, and even to understand modifications.

The primary purpose of a 6.7 Powerstroke Engine Wiring Diagram is to provide clarity and precision. When a component isn't working as it should, the diagram allows for systematic troubleshooting. You can follow a wire from its origin to its destination, checking for continuity, voltage, and ground. This organized approach saves time and prevents unnecessary replacement of parts. The diagram also helps in understanding the functions of various sensors, such as:

- Mass Airflow (MAF) Sensor

- Exhaust Gas Temperature (EGT) Sensors

- Crankshaft Position Sensor

- Camshaft Position Sensor

Furthermore, these diagrams are indispensable for understanding the intricate communication between the Engine Control Module (ECM) and other systems like the transmission, fuel injection system, and emissions controls. The importance of a detailed and accurate 6.7 Powerstroke Engine Wiring Diagram cannot be overstated for anyone working on these vehicles. It provides the fundamental knowledge needed to ensure every electrical connection is sound and every component is functioning correctly.

Here's a simplified look at how you might use it:

- Identify the suspected faulty component.

- Locate that component on the wiring diagram.

- Trace the wiring harness connected to it.

- Identify the corresponding pins on the ECM or other modules.

- Perform electrical tests (voltage, resistance, continuity) at specific points indicated by the diagram.

For instance, a common issue might involve a specific injector. The diagram would show precisely which wire in the harness controls that injector and what voltage signals it should receive from the ECM. Understanding this allows a technician to:

| Test Point | Expected Reading |

|---|---|

| Injector Control Wire (at injector) | Voltage signal from ECM |

| Injector Ground Wire | Continuity to chassis ground |

If you're looking to delve deeper into the electrical systems of your 6.7 Powerstroke, a reliable source for the 6.7 Powerstroke Engine Wiring Diagram is essential. The information provided in the following section offers comprehensive details and will be your guide.