Understanding the 6es7 331 7pf01 0ab0 wiring diagram is crucial for anyone working with Siemens S7-300 PLC systems. This specific module, the 6ES7 331-7PF01-0AB0, is a high-speed analog input module, and its accurate wiring ensures reliable data acquisition. This article will break down what this diagram represents and how to effectively use it.

Decoding the 6ES7 331-7PF01-0AB0 Wiring Diagram

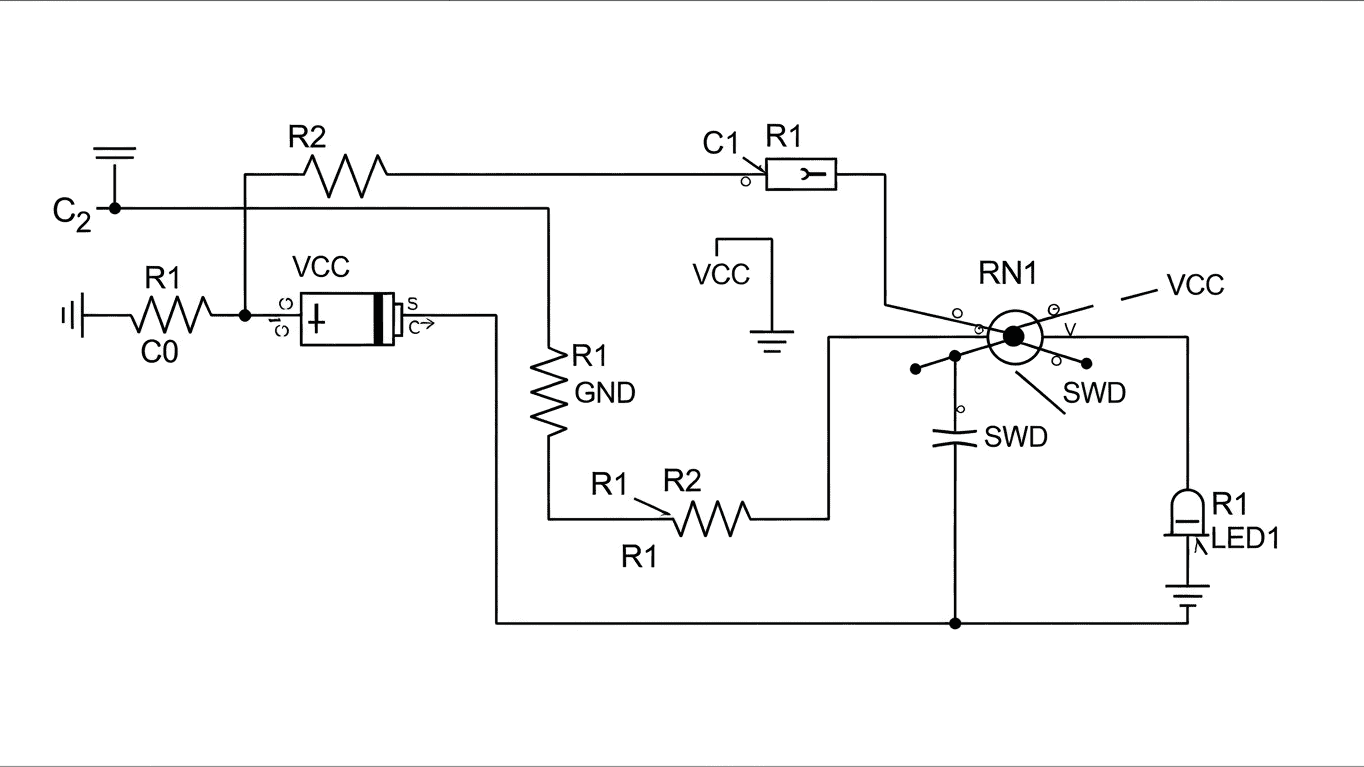

The 6ES7 331-7PF01-0AB0 wiring diagram is a schematic representation that details how to physically connect sensors, transmitters, and other field devices to the analog input module. It shows the terminal layout of the module and specifies which terminal corresponds to each input channel, as well as power and ground connections. This diagram is the blueprint for ensuring that your analog signals are correctly interpreted by the PLC. The importance of a correctly implemented wiring diagram cannot be overstated; errors can lead to incorrect measurements, system malfunctions, and even damage to the equipment.

When consulting the 6ES7 331-7PF01-0AB0 wiring diagram, you will typically encounter information such as:

- Terminal designations (e.g., I+1, I-1, M for channel 1).

- Input type supported (e.g., voltage, current, thermocouple).

- Polarity of connections for each input.

- Internal circuit references, which can help in troubleshooting.

For the 6ES7 331-7PF01-0AB0, the diagram will be particularly specific about its capabilities, such as its high-speed nature and its ability to handle different sensor types. A typical wiring configuration might look like this:

| Module Terminal | Connection Type | Example Device Connection |

|---|---|---|

| I+1 | Positive input for Channel 1 | Positive terminal of a temperature sensor |

| I-1 | Negative input for Channel 1 | Negative terminal of a temperature sensor |

| M | Common/Ground | Ground terminal of the sensor |

Following the diagram precisely ensures that the module receives the analog signals in the correct format and voltage/current range. This is vital for the PLC to accurately convert these raw signals into usable digital data for control processes.

The wiring diagram serves multiple purposes throughout the lifecycle of an automation project. Initially, it guides the installation electrician during the physical setup of the system. Later, it becomes an invaluable troubleshooting tool when a sensor or an input channel is not performing as expected. Technicians can refer to the 6ES7 331-7PF01-0AB0 wiring diagram to verify connections, identify potential wiring faults, and isolate issues quickly. The diagram also plays a role in system documentation, providing a clear record of how the hardware is interconnected.

For detailed and accurate wiring information, always refer to the official Siemens documentation that accompanies your 6ES7 331-7PF01-0AB0 module. The official manual provides the most up-to-date and specific guidance. You can find this essential resource directly from the manufacturer's technical publications.