The 6es7214 1ag40 0xb0 wiring diagram is a critical document for anyone working with Siemens S7-200 series programmable logic controllers (PLCs), specifically the CPU 214 model with the 1AG40 variant. This diagram acts as a blueprint, illustrating the physical connections required to integrate the PLC into an industrial automation system. Without a clear understanding of the 6es7214 1ag40 0xb0 wiring diagram, setting up and troubleshooting these PLCs would be a significantly more complex and error-prone task.

What is the 6es7214 1ag40 0xb0 Wiring Diagram and Its Purpose?

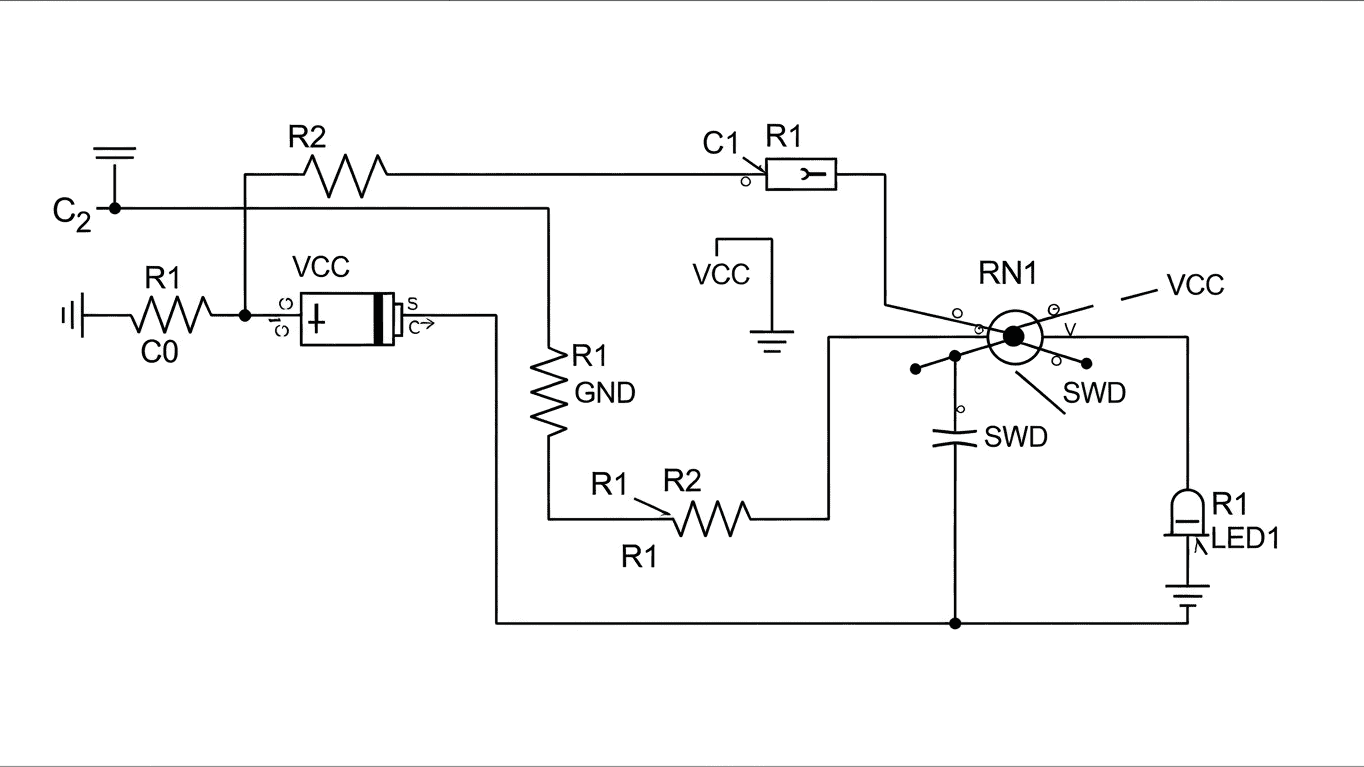

The 6es7214 1ag40 0xb0 wiring diagram is a visual representation that details how the various terminals on the Siemens 6ES7214-1AG40-0XB0 CPU module should be connected to external devices. These external devices can include sensors, actuators, power supplies, communication modules, and other control components. The diagram breaks down these connections into logical sections, often showing:

- Digital input and output terminal assignments

- Analog input and output terminal assignments

- Power supply connections

- Communication port wiring

- Grounding points

Essentially, it's a step-by-step guide for electricians and automation technicians to ensure that the PLC receives the correct signals and can send the appropriate commands to the machinery it controls. The clarity and accuracy of the 6es7214 1ag40 0xb0 wiring diagram are paramount for a safe and functional installation. Proper wiring, as dictated by the diagram, is fundamental for the reliable operation and longevity of the PLC and the entire automation system.

The usage of this diagram spans several phases of an automation project. During the initial installation, it serves as the primary reference for physically connecting wires to the PLC. This includes:

- Identifying the correct terminal for each I/O point based on the PLC's programming.

- Ensuring correct voltage and current ratings for connected devices.

- Implementing proper grounding techniques to prevent electrical noise and ensure safety.

Troubleshooting is another significant area where the wiring diagram proves invaluable. When a system isn't performing as expected, technicians use the diagram to trace signal paths, check for loose connections, or identify incorrectly wired components. A typical troubleshooting scenario might involve:

| Problem | Diagram Check Point |

|---|---|

| Input signal not received | Verify connection to the correct digital input terminal on the 6ES7214-1AG40-0XB0. |

| Output not activating | Confirm wiring to the appropriate digital output terminal and check power supply to the actuator. |

| PLC error code | Consult the diagram for related terminal or power issues that might trigger the error. |

The 6es7214 1ag40 0xb0 wiring diagram is not just a static document; it's an active tool that supports the entire lifecycle of an automation solution, from initial setup to ongoing maintenance and upgrades.

For detailed, accurate, and comprehensive information on the 6es7214 1ag40 0xb0 wiring diagram, please refer to the official Siemens documentation.