Navigating the intricacies of industrial automation often involves deciphering complex documentation. For those working with Siemens SIMATIC S7-300 PLCs, understanding the 6ES7331-1KF02-0AB0 wiring diagram is crucial. This diagram serves as the blueprint for connecting analog input modules, ensuring accurate signal transmission and reliable system operation. Let's delve into what this specific wiring diagram entails and why it is so important.

The Essentials of the 6ES7331-1KF02-0AB0 Wiring Diagram

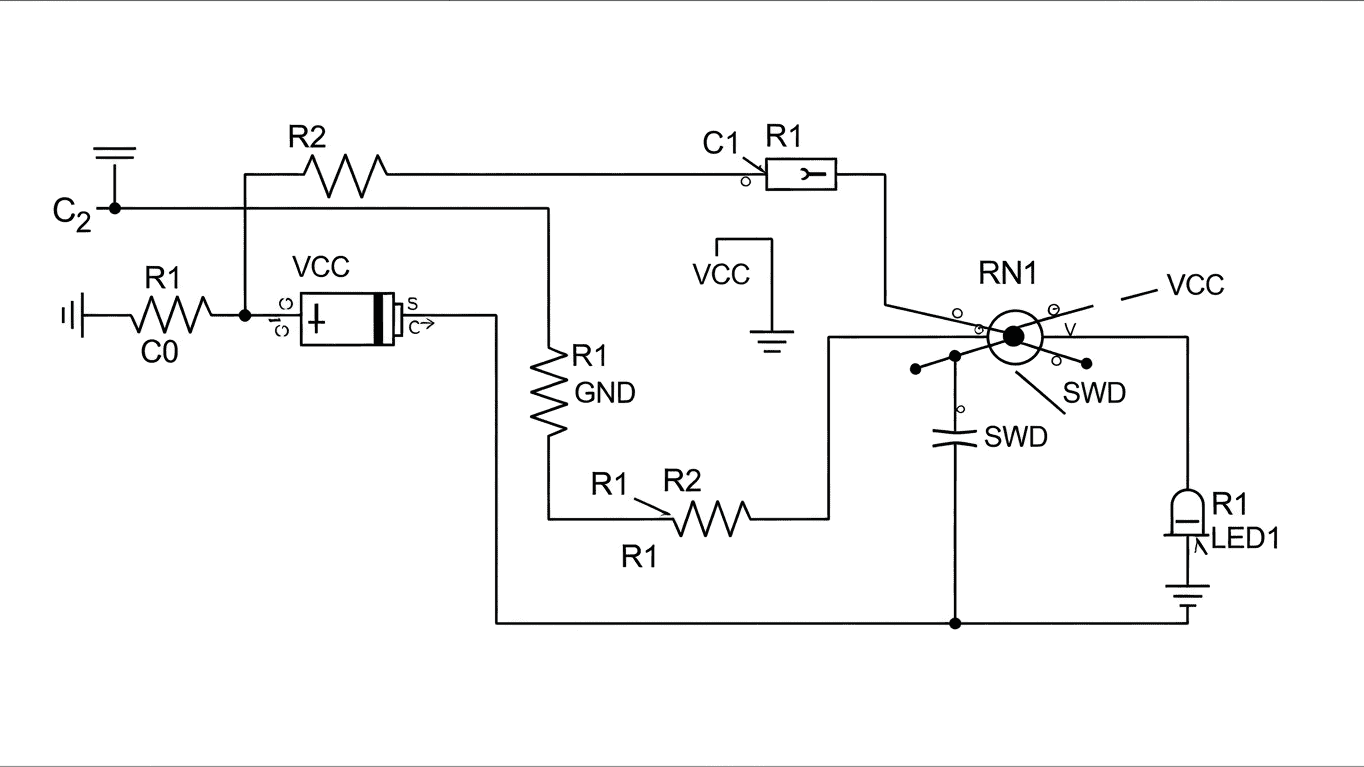

The 6ES7331-1KF02-0AB0 is a specific model of a 4-channel analog input module for the Siemens S7-300 PLC. The associated wiring diagram is an indispensable document that illustrates how to physically connect sensors, transmitters, and other field devices to this module. It provides a clear visual representation of each terminal on the module and its designated function. This includes details on power supply connections, signal input terminals, and any necessary configuration jumpers or settings. Without this diagram, attempting to wire the module would be akin to assembling complex machinery without instructions – prone to errors and potential damage.

The purpose of the 6ES7331-1KF02-0AB0 wiring diagram is multifaceted. Primarily, it ensures the correct voltage and current levels are supplied to the module, preventing electrical shorts or overloads. Secondly, it dictates how analog signals, such as temperature, pressure, or flow readings, are accurately routed from sensors to the PLC's processing unit. This accuracy is paramount for effective process control. Key elements typically found within such a diagram include:

- Terminal identification numbers.

- Designations for signal inputs (e.g., +V, -V, S+).

- Power supply connections (e.g., L+, M).

- Grounding points.

- Specifications for cable types and shielding.

The 6es7331-1kf02-0ab0 wiring diagram is not merely a suggestion; it is a critical requirement for the safe and efficient operation of your automation system. Adhering to the diagram ensures:

- Correct Signal Acquisition: Proper wiring guarantees that the analog signals from your field devices are faithfully converted into digital values by the PLC.

- Module Protection: Following the diagram prevents incorrect power connections that could lead to module failure.

- System Stability: A well-wired system is a stable system, reducing the likelihood of intermittent faults or downtime.

Here's a simplified representation of terminal functions you might find:

| Terminal | Function |

|---|---|

| 1, 5, 9, 13 | Signal Input + |

| 2, 6, 10, 14 | Signal Input - |

| 3, 7, 11, 15 | Signal Common / Ground |

| 4, 8, 12, 16 | Not Connected (NC) or configuration specific |

| L+ | Positive Power Supply |

| M | Negative Power Supply / Ground |

The importance of meticulously following the 6ES7331-1KF02-0AB0 wiring diagram cannot be overstated for ensuring the integrity and performance of your industrial control system.

To ensure your analog input module is connected correctly and functioning optimally, please refer to the detailed documentation provided in the section below, which specifically outlines the 6ES7331-1KF02-0AB0 wiring diagram.