Understanding a 7 Pin Cdi Wiring Diagram is crucial for anyone working with or troubleshooting the ignition system of a motorcycle, scooter, or ATV. This diagram serves as a blueprint, detailing how the various electrical components connect to the Capacitor Discharge Ignition (CDI) unit. Whether you're performing maintenance, installing a new CDI, or diagnosing a no-spark issue, a clear grasp of the 7 Pin Cdi Wiring Diagram will be your most valuable tool.

What is a 7 Pin Cdi Wiring Diagram and How is it Used?

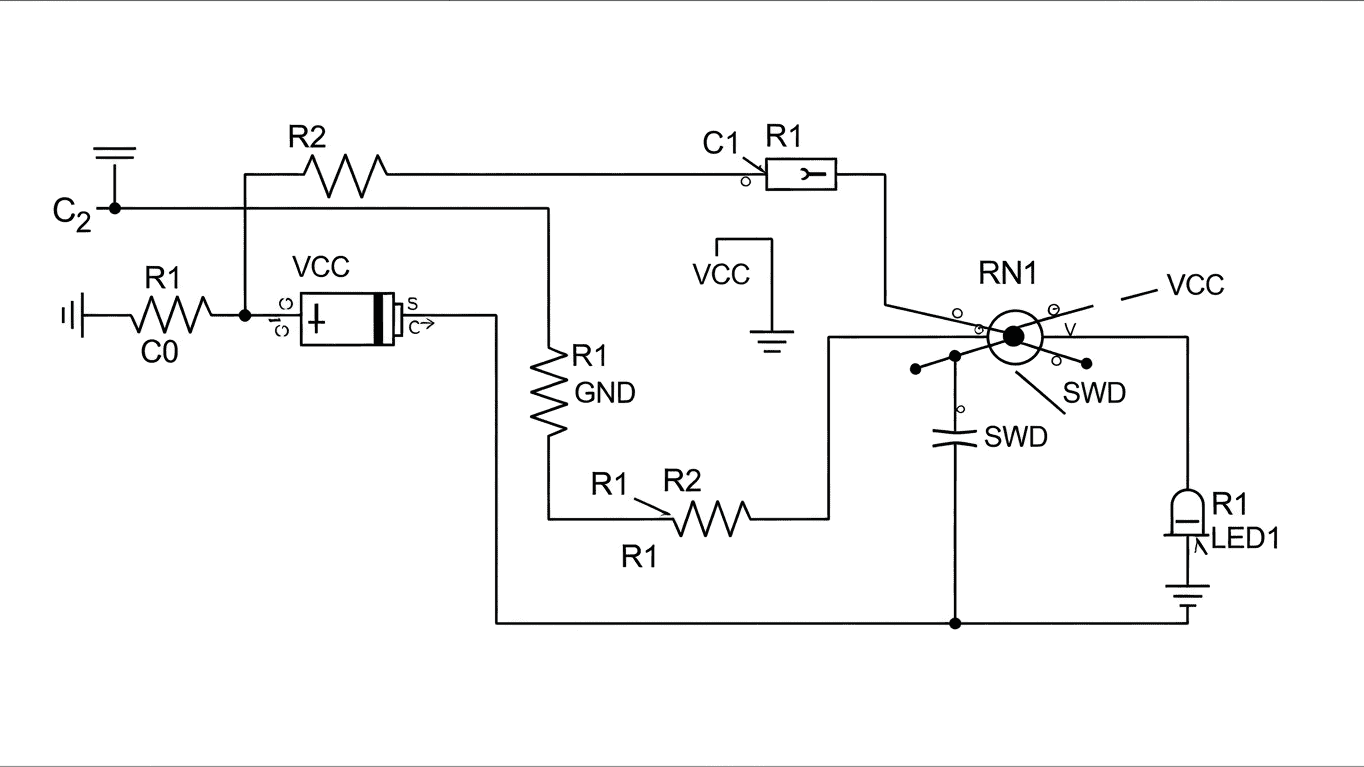

A 7 Pin Cdi Wiring Diagram visually represents the electrical connections for a specific type of CDI unit that features seven pins. The CDI itself is the heart of the ignition system, responsible for generating the high-voltage spark that ignites the fuel-air mixture in the engine's cylinder. It achieves this by storing electrical energy in a capacitor and then rapidly discharging it through the ignition coil. The seven pins on the CDI unit correspond to different functions within the ignition circuit, and the wiring diagram shows precisely where each wire from the motorcycle's harness should connect to these pins.

The primary purpose of a 7 Pin Cdi Wiring Diagram is to guide technicians and enthusiasts through the correct installation and troubleshooting process. Without it, attempting to connect wires or diagnose problems would be guesswork, potentially leading to further damage or incorrect operation. Here's a breakdown of common pin functions you'll find, though specific assignments can vary slightly between manufacturers:

- Power Input (from battery or stator)

- Ground

- Ignition Coil Trigger

- Engine Kill Switch Input

- Stator Signal (for timing)

- Rev Limiter Signal (if applicable)

- Other Sensor Inputs (e.g., gear position)

Using a 7 Pin Cdi Wiring Diagram effectively involves carefully identifying each wire's function on your vehicle and matching it to the corresponding pin on the CDI unit as shown in the diagram. For example, a troubleshooting guide might direct you to check for voltage at the power input pin using a multimeter. If there's no voltage, the problem lies upstream in the charging system or wiring harness. Conversely, if voltage is present but there's no spark, the issue could be the CDI unit itself or a connection issue at the ignition coil trigger pin. The importance of following the diagram precisely cannot be overstated; incorrect wiring can lead to immediate component failure or persistent ignition problems.

Here’s a simplified table illustrating typical pin assignments and their roles:

| Pin Number | Typical Function |

|---|---|

| 1 | Power In (DC/AC) |

| 2 | Ground |

| 3 | Ignition Coil Output |

| 4 | Kill Switch |

| 5 | Pickup Coil/Stator Signal |

| 6 | Rev Limiter (if equipped) |

| 7 | Engine Sensor (e.g., Gear Position) |

To ensure you have the most accurate information for your specific vehicle, always refer to the detailed 7 Pin Cdi Wiring Diagram provided by the manufacturer or a reputable service manual for your make and model.

For a comprehensive and accurate guide tailored to your specific needs, please refer to the detailed 7 Pin Cdi Wiring Diagram resources available in the section that follows this article.