Understanding a 7 Pin Tig Foot Pedal Wiring Diagram is crucial for any TIG welder who relies on precise control over their welding process. This diagram serves as a blueprint, detailing how the various electrical connections within the foot pedal translate into actions at your TIG welding machine. Whether you're troubleshooting a faulty pedal, building a custom setup, or simply want to deepen your knowledge, a clear grasp of the 7 Pin Tig Foot Pedal Wiring Diagram will ensure efficient and effective welding.

The Anatomy and Function of a 7-Pin TIG Foot Pedal

A 7-pin TIG foot pedal is a sophisticated control device designed to offer a wide range of adjustments during the welding operation. It connects to your TIG welding machine via a multi-pin connector, typically a 7-pin plug, allowing it to communicate with the machine's internal electronics. The primary function is to control the amperage output of the welding arc. By tilting the pedal forward, you increase the amperage, and by releasing it, you decrease it. This allows for dynamic adjustments, essential for tasks like starting the arc, building heat, and tapering off at the end of a weld. The versatility of a 7-pin connector means it can often handle additional functions beyond just amperage control.

Beyond simple amperage control, the 7-pin configuration opens the door to more advanced features. Depending on the specific TIG welder model and the pedal's design, these additional functions can include:

- Start/Stop function for the gas flow.

- Trigger activation or deactivation.

- Control of high-frequency (HF) start.

- Access to programmed weld settings.

| Pin Number | Typical Function (may vary) |

|---|---|

| 1 | Potentiometer Wiper (Amperage Control) |

| 2 | Potentiometer End (Low Amperage) |

| 3 | Potentiometer End (High Amperage) |

| 4 | Switch Common (for other functions) |

| 5 | Switch Normally Open (e.g., for Gas Start) |

| 6 | Switch Normally Closed (less common) |

| 7 | Chassis Ground/Shielding |

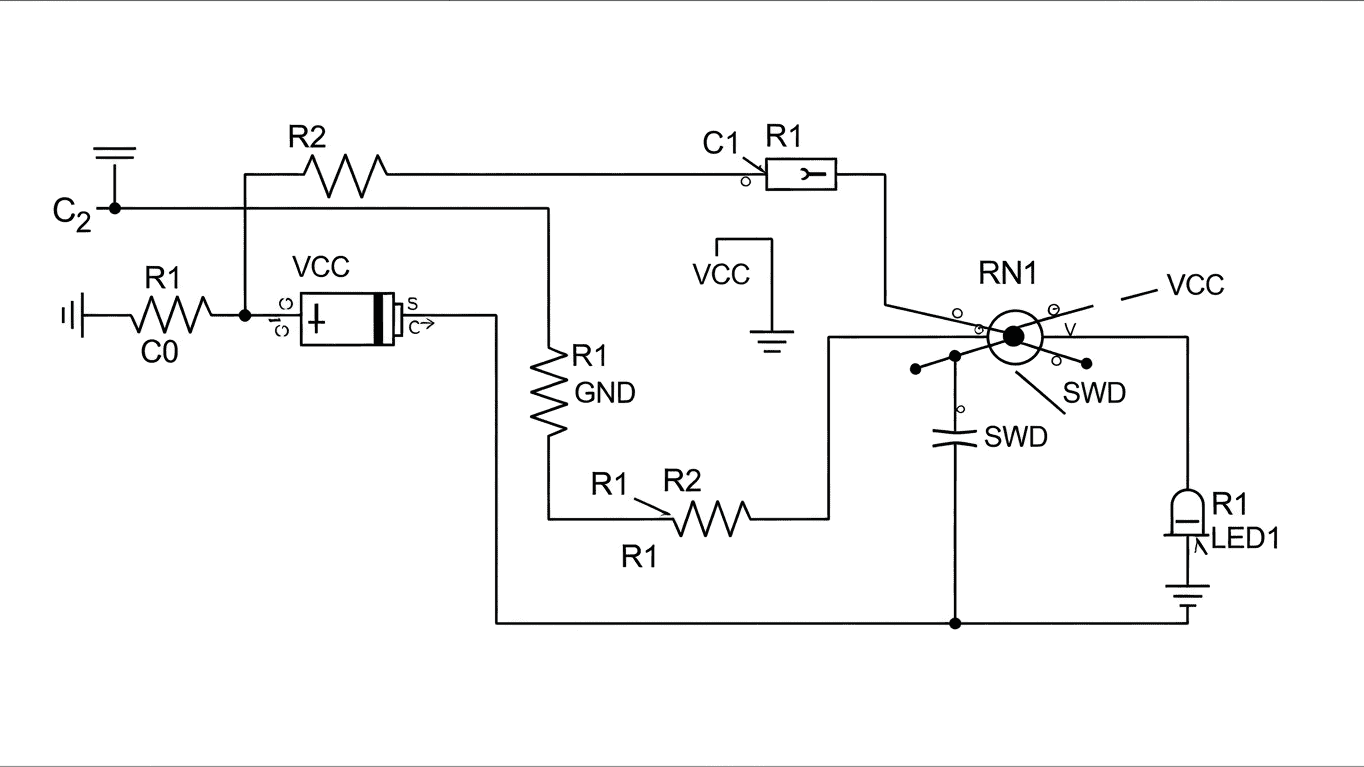

A detailed 7 Pin Tig Foot Pedal Wiring Diagram will visually represent these connections, often using color-coded wires and standardized symbols. It's essential to cross-reference the diagram with your specific TIG welding machine's manual, as pin assignments can differ between manufacturers. A common application is the potentiometer, which acts as a variable resistor. As you press the pedal, the position of the potentiometer's wiper changes, altering the resistance and thus the amperage signal sent to the machine. Other pins might be connected to simple on/off switches that activate secondary functions when the pedal is depressed to a certain point.

If you're looking for the specific wiring for your TIG welding setup, consult the official documentation provided with your equipment. The information within this article offers a general understanding, but the manufacturer's manual for your particular TIG welder and foot pedal is the definitive source for accurate 7 Pin Tig Foot Pedal Wiring Diagram details.