Navigating the intricacies of industrial automation can sometimes feel like deciphering a complex language. For those working with Siemens S7-300 PLCs, understanding specific components is crucial. This article will shed light on the 6es7 331 7nf00 0ab0 wiring diagram, a key piece of information for anyone involved in installing, maintaining, or troubleshooting this particular analog input module.

What is the 6es7 331 7nf00 0ab0 Wiring Diagram and How is it Used?

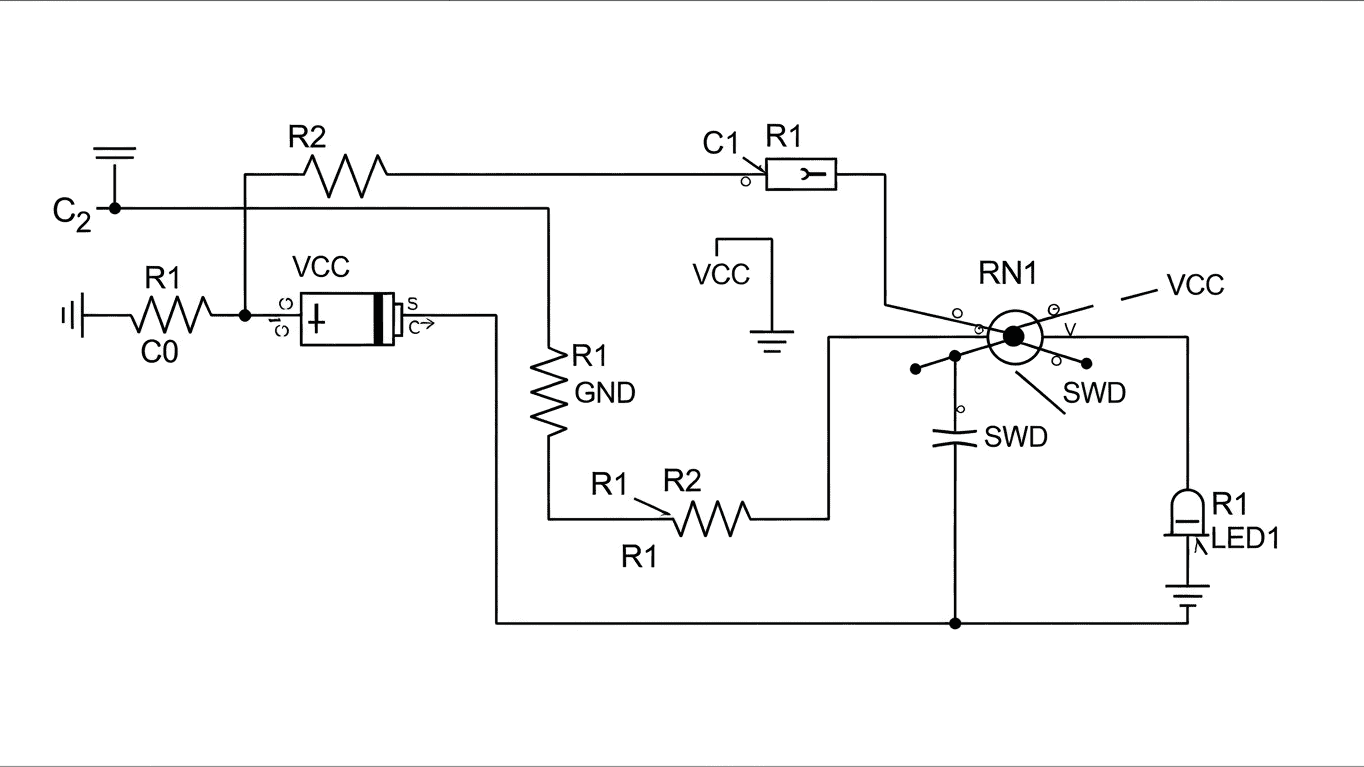

The 6es7 331 7nf00 0ab0 wiring diagram is essentially a blueprint that illustrates how to physically connect input devices and power sources to the Siemens 6es7 331 7NF00 0AB0 analog input module. This module is designed to convert real-world analog signals, such as temperature, pressure, or flow rates, into digital data that the PLC can understand and process. The diagram shows the specific terminals on the module and what type of wiring needs to be connected to each one. This detailed guidance is absolutely essential for ensuring the module functions correctly and safely.

These diagrams are used in several critical phases of automation projects:

- Installation: During the initial setup of the PLC system, technicians use the wiring diagram to ensure all sensors and actuators are connected to the correct terminals on the 6es7 331 7NF00 0AB0 module.

- Troubleshooting: When a problem arises with analog input signals, the wiring diagram becomes an invaluable tool for diagnosing issues. It helps pinpoint potential connection errors, faulty wiring, or incorrect sensor types.

- Maintenance: For routine checks and replacements, having the correct wiring diagram on hand prevents mistakes and ensures that the module is reconnected properly after any maintenance activity.

The information presented in a typical 6es7 331 7nf00 0ab0 wiring diagram includes:

- Terminal designations (e.g., L+, M, I1, I2).

- The type of signal expected at each terminal (e.g., voltage, current).

- Power supply connections.

- Grounding requirements.

- Notes on shielding and cable types.

For example, a simplified representation might look like this:

| Module Terminal | Connection Type | Purpose |

|---|---|---|

| L+ | DC Voltage | Positive power supply |

| M | Ground | Negative power supply/common ground |

| I1 | Analog Input | Connection for the first analog sensor |

Understanding the specific layout and requirements of the 6es7 331 7nf00 0ab0 wiring diagram is fundamental to successful PLC system implementation. It ensures accuracy, prevents damage to equipment, and guarantees the reliable acquisition of process data.

For the most accurate and detailed information regarding the 6es7 331 7nf00 0ab0 wiring diagram, please refer to the official Siemens documentation provided with your module. This documentation is the definitive source for all connection specifications.