Navigating the intricacies of industrial automation can sometimes feel like deciphering a secret code. For those working with Siemens SIMATIC S7-300 systems, understanding the 6es7 321-1bl00-0aa0 wiring diagram is a fundamental step. This diagram acts as the blueprint, guiding the connection of sensors, switches, and other input devices to this specific digital input module, ensuring seamless communication within the automation system.

The Role and Application of the 6es7 321-1bl00-0aa0 Wiring Diagram

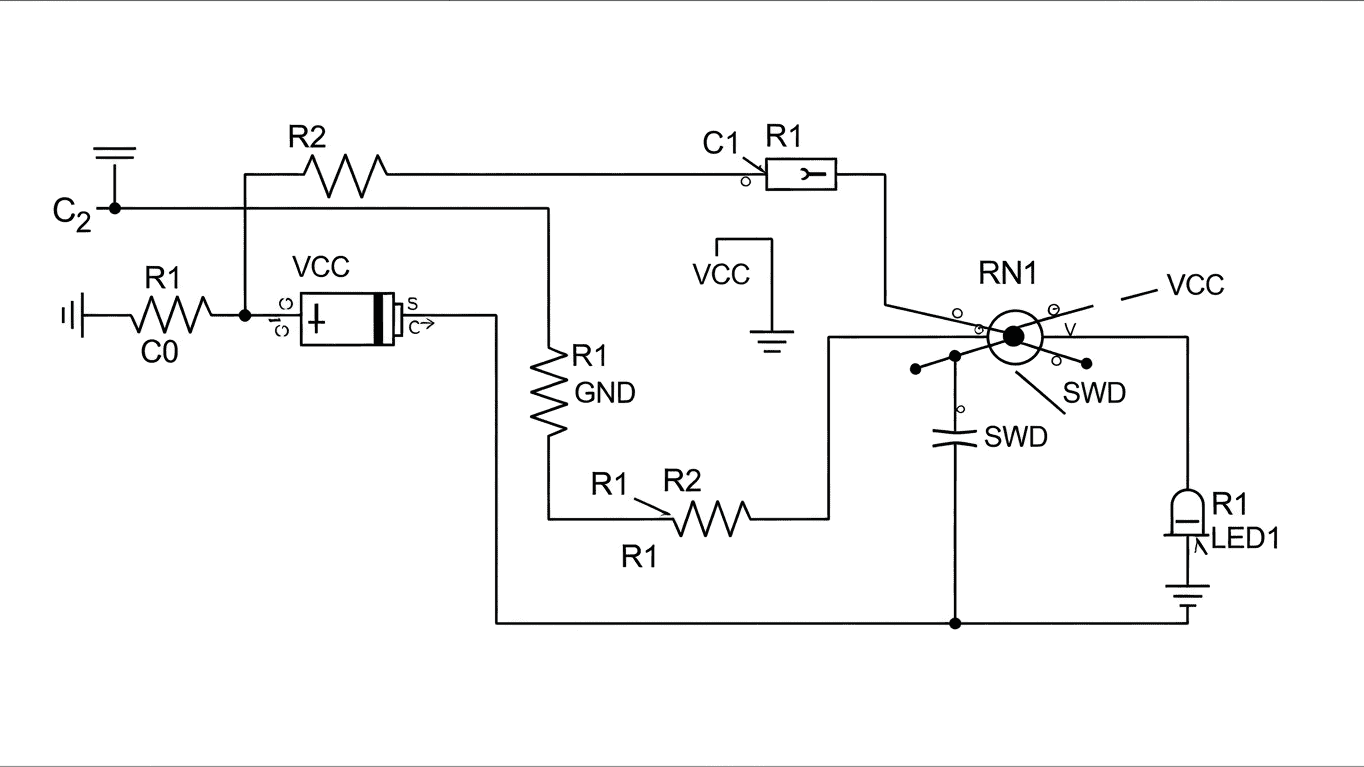

The 6es7 321-1bl00-0aa0 is a digital input module for the Siemens S7-300 PLC. Its primary function is to receive binary signals (ON/OFF, 0/1) from external devices and translate them into a format that the PLC can process. The 6es7 321-1bl00-0aa0 wiring diagram is crucial because it details exactly how these external devices should be physically connected to the module's terminals. Without it, attempting to wire the module would be a shot in the dark, leading to incorrect connections, potential equipment damage, and system malfunction. It ensures that power, signal, and ground connections are made correctly for each of the module's input channels.

The diagram typically illustrates the physical layout of the module, showing the terminal numbers and their corresponding functions. For the 6es7 321-1bl00-0aa0, you'll find details on:

- Power supply connections (e.g., 24V DC)

- Common terminals (C)

- Individual input channels (e.g., I0.0, I0.1, etc.)

- Shield connections for noise reduction

These diagrams are essential for installation, troubleshooting, and maintenance. They allow technicians to quickly identify which wire corresponds to which input, making it easier to diagnose problems when an input signal isn't being received correctly. For instance, if a sensor connected to channel I0.3 is not registering as active, the wiring diagram will guide the technician to check the connections at terminals I0.3 and its associated common terminal.

The importance of a clear and accurate 6es7 321-1bl00-0aa0 wiring diagram cannot be overstated. It's not just about connecting wires; it's about ensuring the integrity and reliability of the entire automation process. A properly wired system is less prone to electrical noise, ground loops, and other interference that can lead to false readings or intermittent failures. The diagram also ensures that the voltage and current requirements of the input devices are compatible with the module's specifications.

Here's a simplified representation of what you might find:

| Terminal | Function |

|---|---|

| L+ | Positive power supply (e.g., +24V DC) |

| M | Negative power supply (Ground) |

| C1 | Common terminal for channels 0-3 |

| I0.0 | Digital Input Channel 0 |

| I0.1 | Digital Input Channel 1 |

| I0.2 | Digital Input Channel 2 |

| I0.3 | Digital Input Channel 3 |

When performing any electrical work on your automation system, always refer to the comprehensive documentation provided with your specific Siemens hardware. For the most detailed and accurate information regarding your 6es7 321-1bl00-0aa0 module, consult the official Siemens documentation, which can typically be found on their support website.